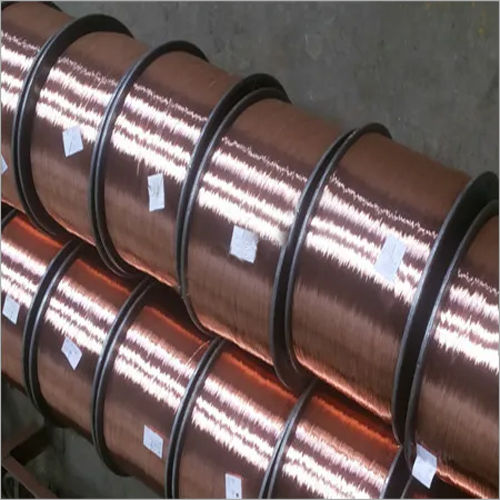

Enamelled Copper Wires

Product Details:

Enamelled Copper Wires Price And Quantity

- 500.00 - 600.00 USD ($)/Kilograms

- 400-500 Kilograms

Enamelled Copper Wires Trade Information

- 1000 Kilograms Per Day

- 1 Week

Product Description

Our company has gained immense recognition in offering a quality assured range of Enamelled Copper Wires Round. The offered wires round is widely used in electric cables and welding machines. Offered wires round is manufactured with high precision by utilizing the finest grade copper under experts direction. This wires round is tested well on numerous quality parameters before it is delivered to clients. Furthermore, this Enamelled Copper Wires Round can be availed by the clients at a very nominal rate.

Features of Enamelled Copper Wires:

- High conductivity

- High tensile strength

- Highly Flexible

Enamelled Magnet Armature Winding Super Enameled Wires Made Of Copper (Round)

We manufacture Enameled Copper wire round in the size range from 0.05 mm to 5.0 mm in various insulation systems such as Modified Polyester, PVA, Polyester imide, Thiec Modified Polyester, Polyester imide over coated with Polyamide imide, Modified Polyester over coated with Polyamide, Solderable, Solderable with Epoxy, with a temperature index from 155oC to 220oC.

Our products comply with IEC 69317, IS 13730, NEMA 1000, and also can be produced according to customer's requirements. We can offer Round Wires in packing of 5 Kgs up to 400 Kgs.

We also manufacture in various builds / covering in accordance to the customers requirements.

Our enamelled wires are extensively used in Transformer, Alternators, Rotating Machinery / Electric Motor, White Goods (Fans, Washing Machine Motors, Air-Conditioner Compressor Motors, Degaussing Coils, Deflection Coils, Etc), Auto Electrical (Dynamo, Alternators, Wiper Motors, Horns, Window Motors, Ignition Coils, Etc), Luminaries( Ballast, Chocks,) Electronics, Switch Gear (ELCB, MCCB, RCCB, Dimmerstats, Relays, Etc), Pumps, Turbines, Windmills And Other Electrical Equipments.

Conversion Chart of SWG and SWG

| Metric Conversion based on B.S. 350 : 1 in. - 25.4 mm ; 1 sq. in. = 645.16 sq. mm. | ||||

| S.W.G. No. | Dia inch | Sectional Area sq. inch | Dia mm. | Sectional Area sq. mm. |

| 7/0 | 0.5 | 0.19635 | 12.7 | 126.677 |

| 7/0 | 0.482 | 0.182467 | 12.2428 | 117.72 |

| 6/0 | 0.464 | 0.169093 | 11.7856 | 109.092 |

| 6/0 | 0.448 | 0.157633 | 11.3792 | 101.699 |

| 5/0 | 0.464 | 0.169093 | 11.7856 | 109.092 |

| 5/0 | 0.448 | 0.157633 | 11.3792 | 101.699 |

Conductor Properties of Enamelled Copper Wires :

| Physical properties of annealed copper | ||

| Density at 20°C | g/cubic centimeter | 8.89 |

| Thermal Conductivity | G.cal/mm/sec/cm | 0.93 |

| Thermal capacity | ||

| Thermal Expansion - Linear (change in unit | 16.8X10 -6 | |

| length at 0°C | ||

| Melting Point | Deg C | 1083 |

| Tensile strength of annealed copper wire | ||

| Ultimate strength | kg force /mm | 25.3-28.1 |

| Yield strength | kg force /mm | 6.3-8.4 |

| Electrical properties of annealed copper wire | ||

| IACS Volume conductivity, min at 20 deg C | % | 100 min. |

| Volume resistivity, max. at 20 deg C | Ohm. mm/m | 0.017241(1/58) |

| Weight Resistivity, Maximum at 20 deg C | Ohm gramme/meter | 0.15328 |

| Thermal Coefficient of resistance at 20 deg C (change in unit resistance at 20 deg C/°C | 0.00393 | |

Technical Specifications of Enamelled Copper Wires

| Type of enamelled wire | High mechanical/ | Self solderable/ | General/ | High mechanical/ | High Thermal | High | High | Self | Self | Self | High | Self |

| High | General/ | Self solderable/ | Self solderable/ | Self bonding | General/ | General/ | Self solderable/ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | IS : 13730-1/ | IS : 13730-2/ | IS : 13730-3/ | IS : 13730-4/ | IS : 13730-7/ | IS : 13730-8/ | IS : 13730-13/ | IS : 13730-19/ | IS : 13730-20/ | IS : 13730-21/ | IS : 13730-22/ | IS : 13730-23/ | IS : 13730 (Under/ | IS : 13730-26/ | IS : 13730-34/ | IS : 13730-35/ | IS : 13730-36/ | IS : 13730-37/ | IS : 13730-45/ | IS : 13730-54/ | IS : 13730-51/ |

| THERMAL CLASS | 130 (B) | 130 (B) | 155 (F) | 130 (B) | 200 | 180 (H) | 200 (C) | 130 (B) | 155 (F) | 155 (F) | 180 (H) | 180 (H) | 155 (F) | 200 (C) | 130 (B) | 155 (F) | 180 (H) | 180 (H) | 130 (B) | 155 (F) | 180 (H) |

| Chemical base of base/ Single coat | Modified | Polyurethane | Modified | Polyurethane | Polyimide | Polyesterimide | Theicpolyester/ | Polyurethane | Polyurethane | Polyurethane | Polyester/ | Polyesterimide | Polyester | Polyamideimide | Polyester | Polyurethane | Polyesterimide | Polyesterimide | Polyester | Polyester | Polyurethane |

| Chemical base of top coat |

| Polyvinyl |

|

|

|

| Polyamideimide | Nylon |

| Nylon | Nylon |

|

|

|

| Polyvinyl | Polyvinyl | Polyvinyl |

|

|

|

| Range of Wire (Diameter) | 5.000-0.500 mm | 2.000-0.050 mm | 5.000-0.050 mm | 2.000-0.050 mm | 5.000-0.020 mm | 5.000-0.050 mm | 5.000-0.050 mm | 2.000-0.050 mm | 0.800-0.050 mm | 1.60-0.050 mm | 5.000-0.050 mm | 1.60-0.050 mm | 1.60-0.254 mm | 1.60-0.071 mm | 5.000-0.050 mm | 0.800-0.050 mm | 1.60-0.050 mm | 1.60-0.050 mm | 5.000-0.050 mm | 5.000-0.050 mm | 1.00-0.050 mm |

| Insulation Range | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1 & 2 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1b,2b & 3b | Grade 1b,2b & 3b | Grade 1b,2b & 3b | Grade 1,2 & 3 | Grade 1,2 & 3 | Grade 1,2 & 3 |

| Standard colour | Golden Yellow | As per | Light Brown/ | As per | Golden Yellow | Light Brown/ | Light Brown/ | As per | As per | As per | Medium Brown to | Light Brown | As per | Light Brown | Medium Brown | As per | Light Brown/ | Light Brown/ | Light Brown/ | Light Brown/ | As per |

| UL Listed | File No. : None | File No. : None | File No. : None | File No. : None | File No. : None | File No. : None | File No. : E174288 |

| File No. : E174288 |

| File No. : E174288 |

| File No. : E174288 |

|

|

|

|

|

|

|

|

| TECHNICAL PROPERTIES AS PER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Heat shock (°C) | 155 | 155 | 175 | 155 | 240 | 200 | 220 | 155 | 175 | 175 | 200 | 200 | 175 | 220 | 155 | 175 | 200 | 200 | 155 | 175 | 200 |

| Cut through (°C) | 170 | 170 | 240 | 170 | 400 | 300 | 320 | 170 | 200 | 200 | 265 | 265 | 240 | 350 | 240 | 200 | 265 | 300 | 240 | 240 | 240 |

| Solderable temperature (°C) | Not applicable | 375 | Not applicable | 375 | Not applicable | Not applicable | Not applicable | 375 | 390 | 390 | Not applicable | 470 | Not applicable | Not applicable | Not applicable | 390 | 470 | Not applicable | Not applicable | Not applicable | 450 |

| Resistance to Abrasion for 1.00mm | >11.3 | >9.3 | >10.4 | >9.3 | >6.6 | >10.9 | >11.3 | >9.3 | >8.3 | >9.3 | >10.9 | >10.9 | >10.0 | >7.05 | >10.4 | >8.1 | >10.9 | >10.9 | >10.4 | >10.4 | >7.8 |

| Resistance to refrigerants | Very good | Not applicable | Not applicable | Not applicable | Very good | Good | Very good | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Very good | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable |

| Flexibility & Adherence | Very good | Good | Good | Good | Very good | Good | Very good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good |

| Bonding Temperature (°C) | Not applicable | 170/200 depending | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable | 170/200 depending | 170/200 depending | 170/200 depending | Not applicable | Not applicable | Not applicable |

| SPECIAL CHARACTERSISTICS | High | Solderable, | Upgraded | Self solderable | Designed | Good | Very good | Low coefficient of | Self solderable | Low coefficient of | Used in all 180°C | Self solderable | Good mechanical, | High burnout | Good thermal & | Solderable, | Solderable, | Class 180°C | General purpose | General purpose | Good mechanical, |