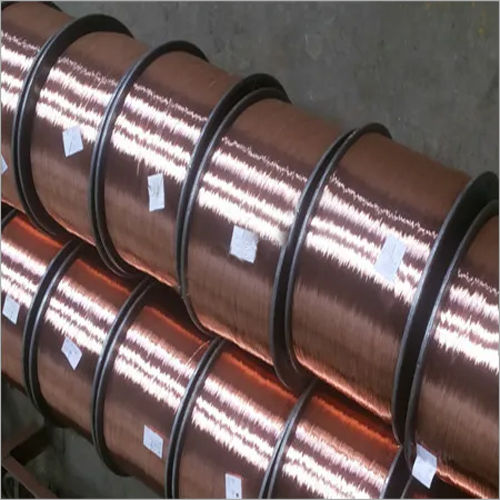

Rectangular Enamelled Copper Wire

Product Details:

- Product Type Rectangular Enamelled Copper Wire

- Material Copper

- Usage Industrial

- Insulation Material Enameled

- Click to view more

Rectangular Enamelled Copper Wire Price And Quantity

- 500 Kilograms

- 775 INR/Kilograms

Rectangular Enamelled Copper Wire Product Specifications

- Enameled

- Rectangular Enamelled Copper Wire

- Industrial

- Copper

Rectangular Enamelled Copper Wire Trade Information

- 1000 Kilograms Per Day

- 1 Week

Product Description

With experience of more fifty years, we are catering huge requirements of our patrons by manufacturing, exporting and supplying premium quality Rectangular Enamelled Copper Wire. Offered in plethora of thickness and diameters, this wire is manufactured by our deft professionals in adherence with international quality standards with the use of optimum quality copper and contemporary techniques. The offered wire is used in motors, transformers, refrigerators, washing machines and many other electrical equipments. Moreover, clients can avail this Rectangular Enamelled Copper Wire at highly competitive prices from us.

Features:

-

High tensile strength

-

Excellent finish

-

Corrosion proof

-

Uniform thickness

Enamelled Magnet Armature Winding Wires Made Of Aluminum Rectangular

We manufacture Rectangular Enamelled Wires up to 70 mm2 in various insulation system and temperature index from 155 D C to 220 Degree C.

Our products comply with IEC 69317, IS 13730, NEMA 1000, and also can be produced according to customer's requirements. We can offer Rectangular Wires in packing of 10 Kgs up to 100 Kgs.

Our enamelled wires are extensively applied in transformer, motor for air-conditioner, refrigerator, ice-box, washing machine, auto motor, compressor, microwave stove, charger, ballast, relay, degaussing coil, etc.

Technical Specification

| Specification | Iec-60317-17 | Iec-60317-18 | Iec-60317-16 | Iec-60317-28 | Iec-60317-29/ | Iec-60317-30 | Iec-60317-58 |

|

|

|---|---|---|---|---|---|---|---|---|---|

| Thermal Class | 105 | 120 | 155 | 180 | 200 | 220/240 | 220 | 120 | 180 |

| Chemical Base Of Base Coat | Polyvinyl Acetal | Polyvinyl Acetal | Polyester | Polyesterimide | Polyesterimide | Polyimide | Polyamide-Imide | Polyvinyl Acetal | Polyesterimide |

| Chemical Base Of Top Coat |

|

|

|

| Polyamide-Imide |

|

| Epoxy-Bond Coat | Epoxy-Bond Coat |

| Range Of Wire (Diameter) | Cross Section Area Up To 80 Sp.Mm, Thickness : From 1.3-8 Mm, Width : From 2.0-16 Mm | ||||||||

| Insulation Range | Iec Grade 1:0.060-0.110, Iec Grade 2:0.120-0.179; | In Addition To Base Coat Increase | |||||||

| Standard Colour | Golden Yellow | Golden Yellow | Brown | Brown | Brown | Light Brown | Light Brown | Golden Yellow | Brown |

| Technical Properties As Per |

|

|

|

|

|

|

|

|

|

| Flexibility & Adherence |

|

|

|

|

|

|

|

|

|

| :Mandrel Bending On Thickness | 2-3 T & 3-4 W | 2-3 T & 3-4 W | 3-4 T & 4-6 W | 3-4 T & 4-6 W | 3-4 T & 4-6 W | 3-4 T & 4-6 W | 3-4 T & 4-6 W | 2-3 T & 3-4 W | 3-4 T & 4-6 W |

| :Adherence (no Crack After | 15 | 15 | 15 | 15 | 15 | 10 | 15 | 15 | 15 |

| Heat Shock No Cracks After | 2-3 T/155 | 2-3 T/155 | 6 T/175 | 6 T/200 | 6 T/200 | 6 T/260 | 6 T/240 | 2-3 T/155 | 6 T/200 |

| Break Down Voltage At Room | Grade 1 : > 1000, Grade 2: >2000 | ||||||||

| Resistance To Hot Transformer Oil | Excellent | Excellent | Not Applicable | Excellent | Excellent | Not Applicable | Not Applicable | Excellent | Excellent |

| Heat Bonding Temperature/Time | Not Applicable | Not Applicable | Not Applicable | Not Applicable | Not Applicable | Not Applicable | Not Applicable | 110 C/48 H Or 120 C/24 H | |

| Special Charactersistics | High Mechanical Strength, Strong | Good Thermal, | High Thermal, | High Thermal, | Very High | Very High | Bondable Coating | Bondable Coating | |